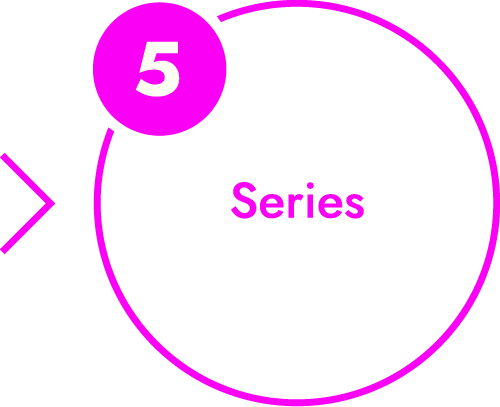

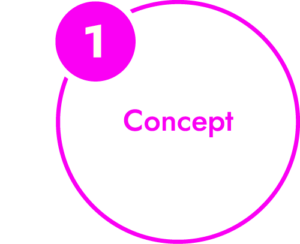

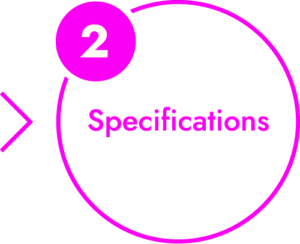

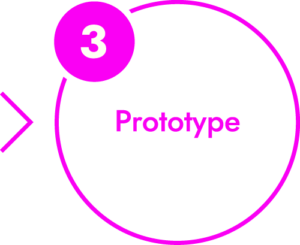

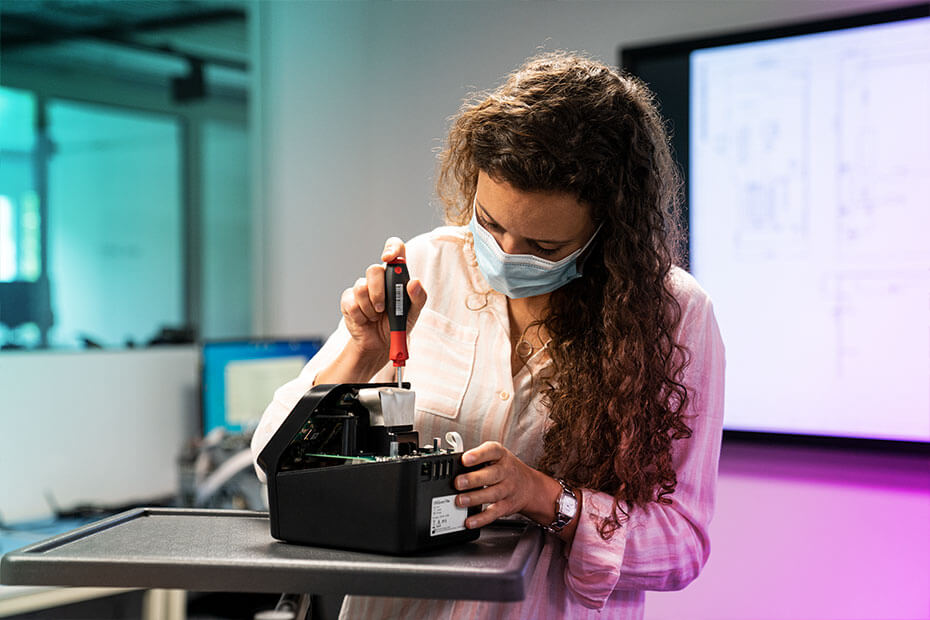

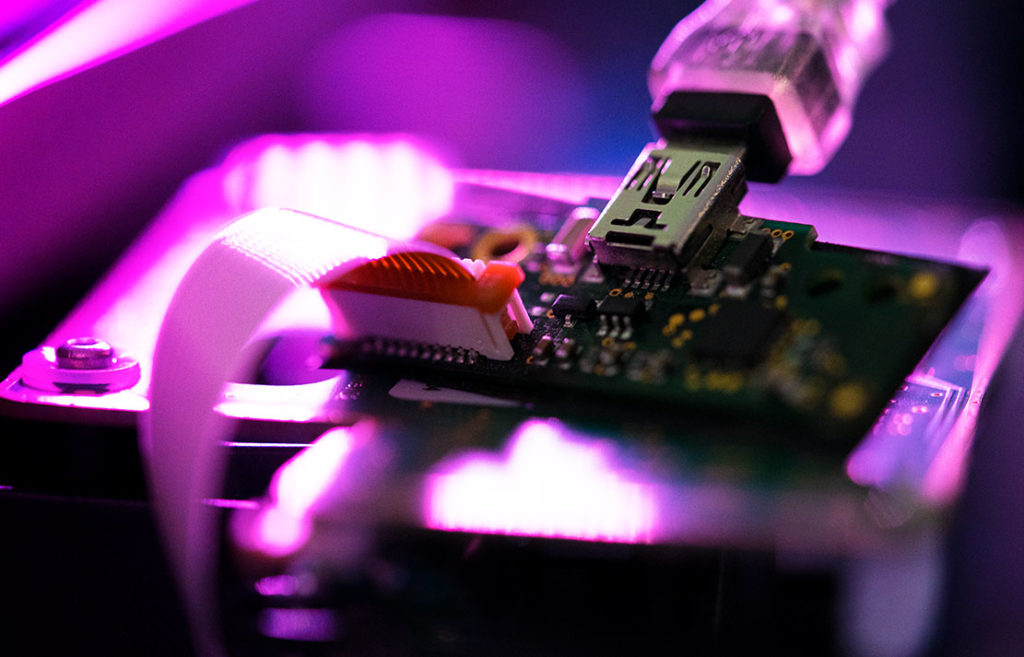

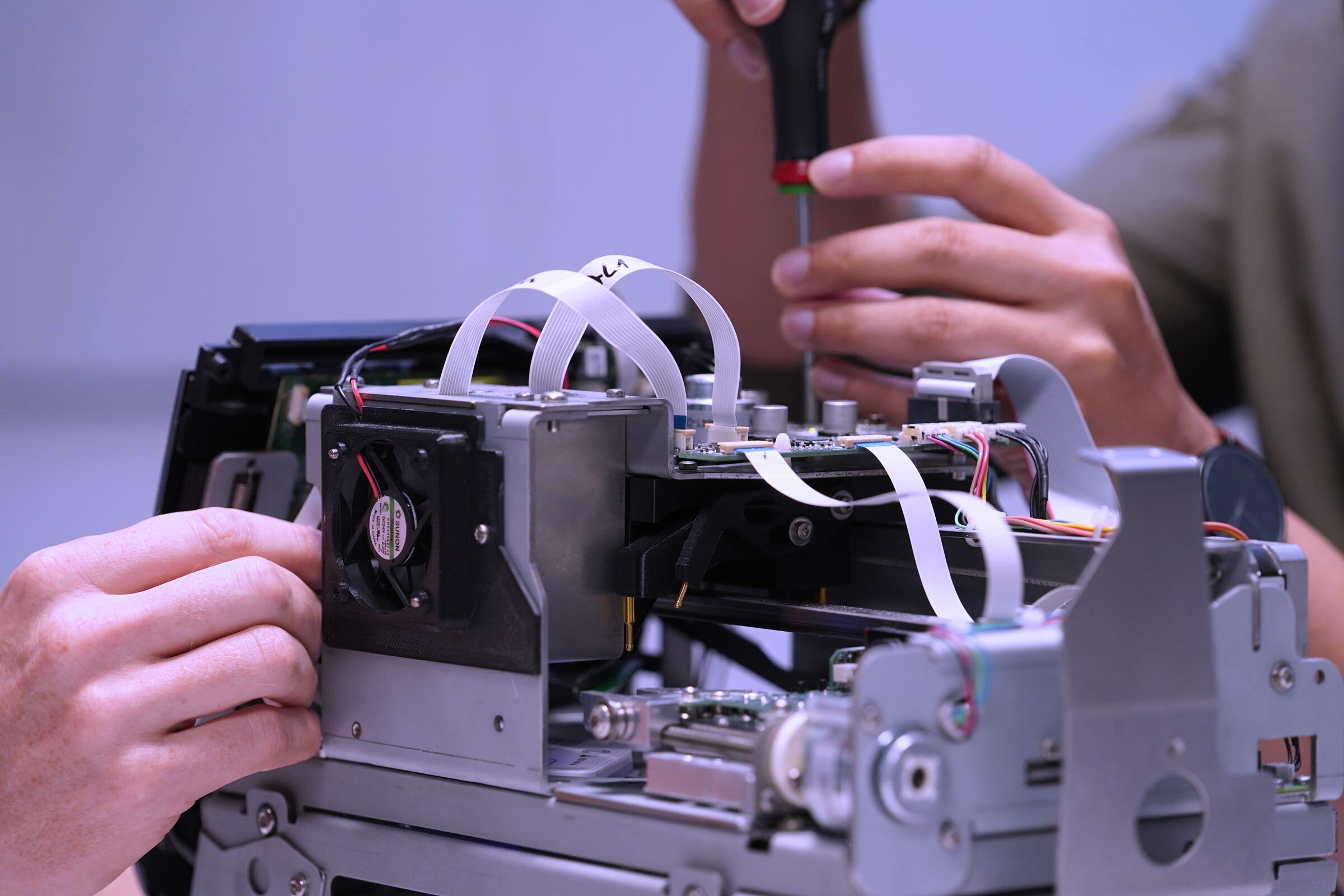

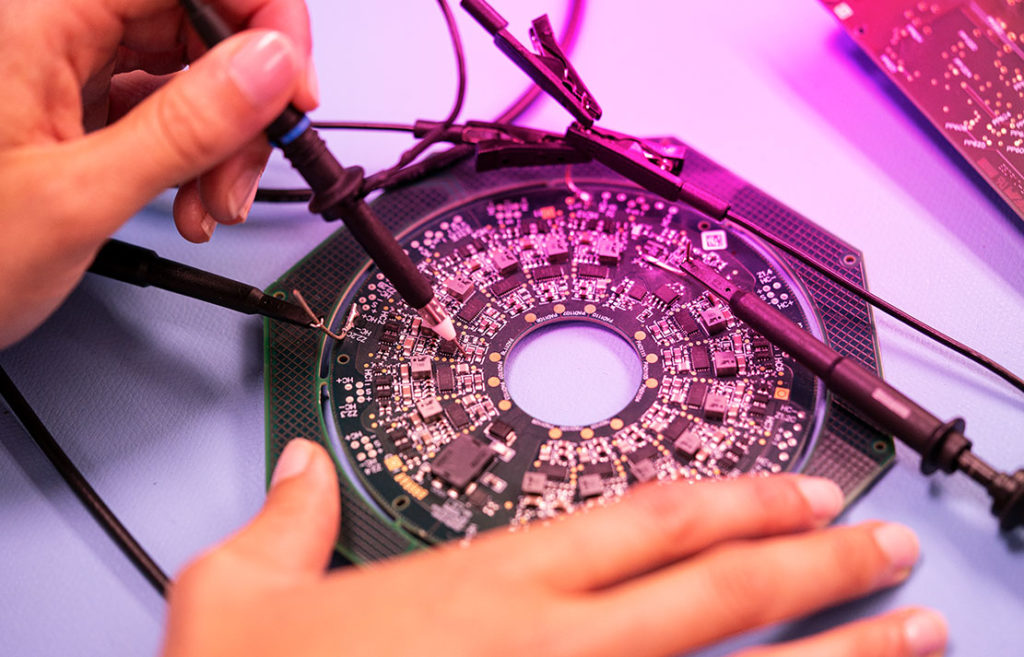

DIALUNOX is your trusted partner for all your manufacturing needs. With our state-of-the-art facilities and cutting-edge technologies, we offer comprehensive solutions to meet the diverse requirements of the clients that are in need of an optical detection device at the point of need.